uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

UV-Oxidation

Photo-Oxidations

RECO - REactorCOntroller

The RECO was an essential step forward for the development of reliable UV technology. A significant part of the hard UV-C light is sensible to voltage fluctuations. For the disinfection and oxidation process to be reliable, the UV performance has to be steady during the process. Therefore, a.c.k. developed and patented the RECO. The RECO constantly compares the parameters measured at the time with the target values of the lamp, which can be seen as a form of the lamp's fingerprint. It is individually stored on a chip-card supplied along with the UV lamp. Any deviation from the target values will be balanced out by the RECO-controller. Thus, the optimal UV output is ensured and will work for your oxidation project.

In doing so, we ensure that the performed power is equal to the nominal power.

The RECO is made of three functional units:

- Measurement instrumentation (in reactor and power supply)

- Microprocessor with display (see photo) with the chip-card of the UV lamp

- Power supply with switch panel (= modulator)

Difference in Performance

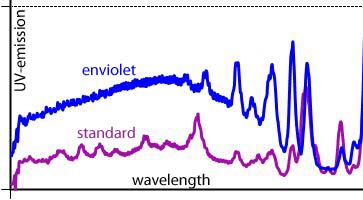

The figure on the left shows the UV-spectra of two "similar" UV-lamps of the hard UV-range.

Blue line: Enviolet-UV lamp operated by RECO-power control system.

Red line: Conventional UV lamp with the same nominal power without permanent power control by RECO-system.

The difference of the UV output is evident. Under the labconditions of this example, the performance of the conventional system prooved 50% of that of the Enviolet-RECO-system. Under real conditions, varying voltage of power supply interferes with this value. This can lead to even higher differences and reduces the performance of a conventional system by 90% of its efficiency under extreme conditions. Such a case would mean that one single Enviolet UV reactor would show the same chemical reaction performance as nine conventional UV reactors with similar nominal power.