uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

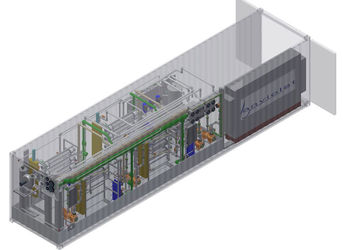

Containerized AOP

No mor space in your building? We will supply your aop including required housing!

We can design aop and UV-oxidation installations for very limited space conditions and install the oxidation equipment compliant to the safety regulations of the aop-container.

Many years of experience in construction and production ensure that no compromises will be made with respect to functionality and longevity of the aop-installation.

During containerizing we take all of the conditions into account for example the climate and we always check if treatment tanks have to be integrated into the aop-container or if it would be possible to keep them outside, still maintaining a best performance of the advanced oxidation process (aop).

The aop-processes themselves can theoretically all be realized as a containerized aop-solution. The only limiting factor, however, is the treatment capacity of a containerized aop-plant. For bigger flow rates, we keep the technology components of the advanced oxidation process within the supplied housing structure, and tanks have to be placed outside in a suitable execution.

Characteristics of Containerized AOP-Plants

The best design of containerized AOP and UV plants with the best operational conditions are recognizable in the details of the construction:

- Integration by concentrated interfaces

- Containers as a structure for an optimal use of space

- in cold regions, insulated containers prove to have better operational conditions

Containerized UV-plants with outside placed treatment tanks

The valuable components like UV-reactors, control-board, pumps, dosing stations, etc. are placed inside the containers; Reaction tanks and storage tanks for chemicals and untreated waste water can easily be designed to be placed outside around the containers. In doing so, flexible and efficient oxidation units can be integrated into places which are tight on space.

The picture also shows how a ready designed UV-reactor system can later be upgraded by an additional 50% of UV-oxidation performance.