uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

MicroUV® - UV Disinfection Reactors, Flow-Through Systems

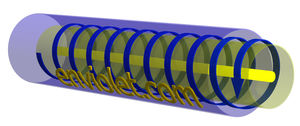

All enviolet disinfection reactors use rotational flow. This guarantees a high turbulence, prevents deposits and enables correct system settings based on exact layout calculations.

- computer-supported design

- turbulent rotational flow

- high-performance lamps

- electric performance regulation

Since September 1996, a.c.k. aqua concept and later also enviolet have been developing special reactors to treat water (disinfection and oxidation).

The founders of enviolet and a.c.k. aqua concept both have ample experience of the design of UV reactors and light sources:

Dr.-Ing. Martin Sörensen had been employed at the DVGW and the Engler- Bunte- Institute where he worked on the development and testing of UV reactors. Furthermore, he was a contributor to the W 294 (the international design base of UV disinfection reactors), and last but not least he had been an active member of the DVGW– an expert commission for “oxidation processes“.

Dipl.-Ing. Jürgen Weckenmann has over 20 years of professional experience in reactor design, engineering and construction.

Together they created a basis to produce a totally new set of UV reactors for disinfection and oxidation, which included several technical advancements. The reactors of the series MicroUV® are constructed in a way, that enables an adaptation of the reactor design to the UV transmission of water. Therefore, the customer receives a product, which fits to his set of parameters without any additional costs.

Up front some general physical principles will be supplied, to establish a basic understanding of the progressive design: Description of theoretical background of UV disinfection

The MicroUV® reactor series are constructed in such a way, that they are adaptable to the spectral properties of the fluid (water). Thus the client receives a system made for his individual application without generating additional costs.

The modular construction is a particular asset of the reactor. Not only does it permit the free choice of material of construction, but also the adaptation to the requirements of the turbulence of the flow. For the equal distribution of the sterilization dose to the single volume elements, UV reactors have to show a narrow residence time behaviour. This can be described by the Bodenstein-number. This value is high enough for the enviolet UV reactors, for us to be able indicate to a nearly ideal plug flow in our reactors. This means that our reactors conform to the most important condition for a safe and economic sterilization.

Together with our product line "tank sterilization" we are able to consequently solve all areas of UV application, while others concentrate their activities solely on the continuous water flow.

This is due to missing concepts for intelligent and economic tank sterilization. Our product series Microspear® and Microfloat® closes this gap.

The MicroUV® - Disinfection reactors are available in two different groups

| Reactor group | Flow | Material | Rotaclean® | UV-Sensor | Flamable Sampling Valve | Window |

| NT | up to 1000 m³/h | SS316 other materials possible | optional | optional | optional | optional |

| BASIC | up to 50 m³/h | Polypropylene | optional | - | - | - |