uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

COD - Elimination by UV-Oxidation in Wastewater Treatment (AOP)

Advanced Oxidation Process (AOP) eliminates recalcitrant COD in wastewater

Enviolet will realize your uv-oxidation wastewater treatment unit for COD / TOC- reduction and simultaneously increase the bioavailability of the treated wastewater. We do this by UV oxidation in combination with various oxidants under varying conditions in efficient processes of photo-oxidation based advanced oxidation processes.

By irradiating the oxidant with uv-light, reactive intermediates like OH-radicals are formed. These highly reactice radicals will react very quickly with the COD dissolved in the wastewater.

When using hydrogen peroxide as an oxidant, the irradiation with uv-light will lead to a homolytic formation of OH radicals (Photo-homolysis):

H2O2 -UV-> 2 OH*

OH radicals react very quickly with any organic compounds dissolved in the wastewater through hydrogen abstraction. Mineral products such as water, sulphate, etc. result as final products (further information regarding chemistry of uv-oxidation) in this advanced oxidation wastewater treatment process.

uv-lamps and uv-reactors need to have a special design for this advanced oxidation process (AOP), otherwise the photo-reaction will quickly go into inhibition, as it turn out to end in a photo-polymerization. The enviolet uv-reactors are specially designed for highest efficiency of uv-oxidation and phtoto-oxidation in strongly absorbing aqueous solutions, and many wastewaters we treat look in the beginning of the UV-oxidation like Coffee or Latte Macchiato, but still get clear during the advanced oxidation process.

The photo-reaction proceeds until the uv-oxidation is complete and then the next process steps can follow to conclude the whole advanced oxidation process (AOP).

COD-elimination in wastewater by batch treatment

Degradation of highly concentrated and recalcitrant COD ind wastewater

If COD in concentrated wastewater has to be lowered or specifically changed in chemical charcacter, we recommend the optimized batch uv-oxidation system as advanced oxidation process. This application is often found in very polluted side stream wastewaters in manufacturing companies in the chemical, pharmaceutical, surface technology, electronics, aerospace and textile industries. Often, the ingredients dissolved in the wastewater are not only highly concentrated, but also toxic or non-biodegradable. These are the best-case applications for Enviolet's advanced UV oxidation technology and processes for industrial wastewater treatment.

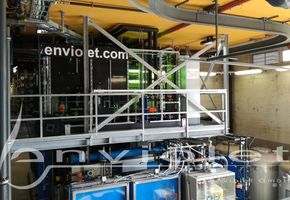

Reduction of COD - Wastewater Treatment by Advanced Oxidation at High Volume Rates

A continuous treatment using uv-oxidation of higher volume rates raises several demands on advanced uv-oxidation plants for a successfull photo-oxidation of pollutants dissolved in wastewater. Besides a high efficiency of the light-induced advanced oxidation processes and low operational cost, the maximum space-time-yield of our uv-reactors is a decisive criterion for photo-induced advanced oxidation processes for wastewater treatment.