uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

MicroUV®-NT

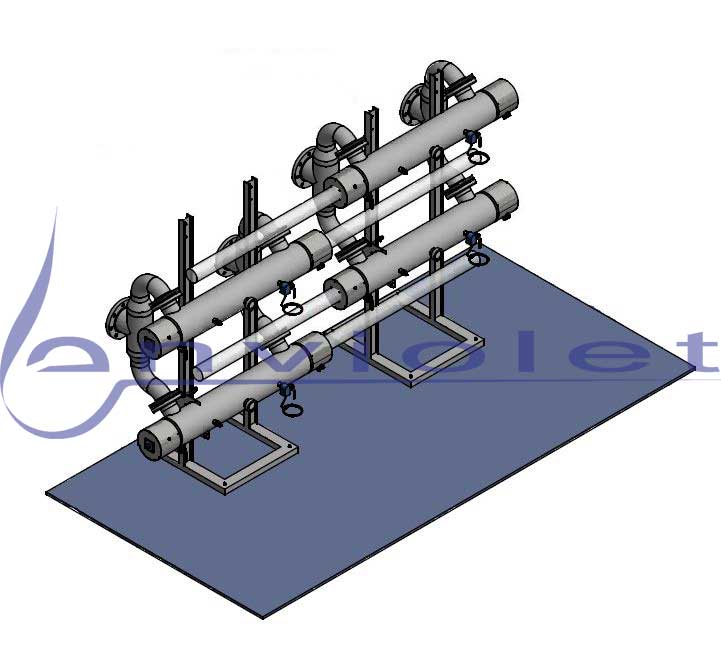

Customized UV disinfection reactors for high flow rates

The enviolet generation of reactors for large-scale use for UV disinfection of flows in the range from 10 to 1000 m³ / h.

In addition to tank disinfection with Microfloat® and Microspear® as well as our MicroUV®-Basic UV reactor series, our MicroUV®-NT reactors represent another pillar of our product range for UV disinfection.

These reactors for the elimination of microorganisms are made of stainless steel according to your specific requirements and can be equipped with a whole range of accessories (such as the Rotaclean®).

The abrasive effect of the rotating flow cleans the reactor continuously and can be perfected by combining it with the Rotaclean® mechanical cleaning device. The Extension series consists of large reactors that are only made of stainless steel (different qualities) and are also used for process media with poor UV transparency.

Information on the theoretical background of the elimination of microorganisms and the reactor design can be found in the section 'Theory of UV disinfection reactors' on our website!

The entire technical equipment is designed for the special customer requirement in order to find a suitable solution for you!

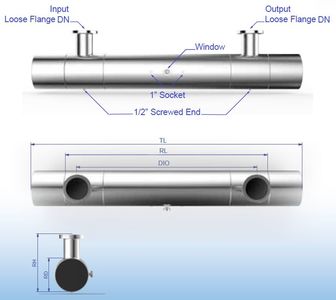

MicroUV®-NT - Types and Data

| Type | max. Flow m³/h | In-/ Outlet DN | TL - Total Length in mm | RL - Reactor Length in mm | DIO Distance In-Outlet in mm | RH Height in mm | RD Diameter in mm |

| MicroUV®-NT70 | 72 | 100 | 1860 | 1515 | 1250 | 405 | 273 |

| MicroUV®-NT140 | 144 | 150 | 1860 | 1515 | 1200 | 455 | 318 |

| MicroUV®-NT210 | 216 | 200 | 1860 | 1515 | 1150 | 455 | 318 |

| MicroUV®-NT280 | 288 | 250 | 1860 | 1515 | 1100 | 455 | 318 |

| MicroUV®-NT350 | 359 | 300 | 2400 | 1950 | 1400 | 590 | 406 |

| MicroUV®-NT420 | 431 | 300 | 2400 | 1950 | 1400 | 590 | 406 |

| MicroUV®-NT500 | 503 | 350 | 2400 | 1950 | 1400 | 590 | 406 |

| MicroUV®-NT570 | 575 | 350 | 2400 | 1950 | 1400 | 590 | 406 |

Base parameters of Table: UV-Dose = 400 J/m2 at SAC = 1.32/m; ˜ T10mm = 97% at the end of lamp-life (EOL).

In this table, one can see all kinds of data about the reactor with respect to the specifications.

The Rotaclean® shows a working range from 50% - 100% of the max. flow. For volume rates below 50% the cleaning effect is lower.

What data do we need for reactor design?

1. Flow through the reactor in m³ / h

2. Sample (50mL) or description of the medium to be treated

(e.g .: DI water, process water, rainwater, ...)

3. Temperature of the medium to be treated

Send this data to your contact person or to: info(at)enviolet(dot)com.

We will then send you an offer immediately.