uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

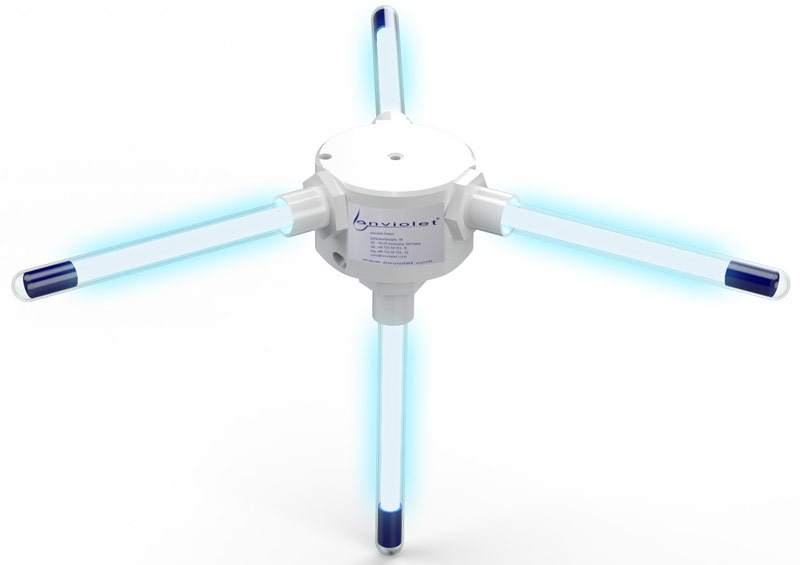

Microfloat®

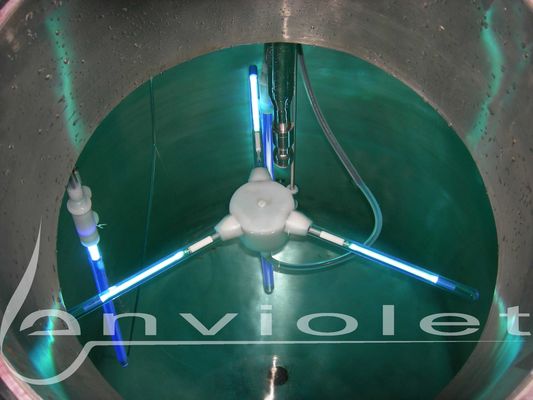

UV-Disinfection of Closed Tanks

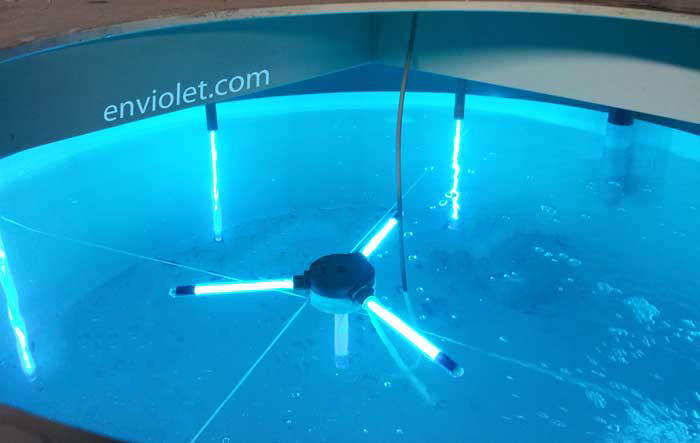

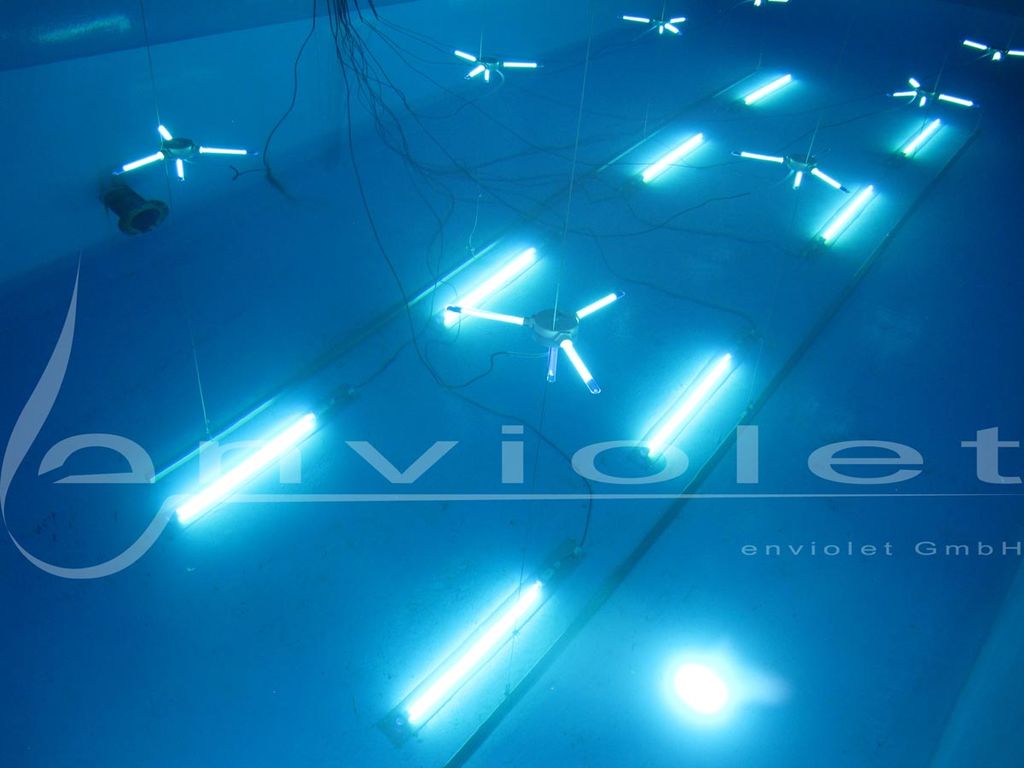

Microfloat® and Microspear® have been specially developed for the chemical-free disinfection of water and other process media in storage tanks and tanks using UVC radiation. Microfloat® (floating UV device) is used in closed tanks with static and also highly fluctuating levels. Microspear® (submersed UV emitter) is mostly used in rinses with static levels and and also for machinery. Often, a combination of Microfloat® and Microspear® is used for disinfection to ensure the optimal coverage of a tank with ultraviolet radiation. Microfloat® irradiates the water and the tank walls above and below the water level with UV-C radiation, so that no biofilm can develop and permanent sterilization is achieved. The ultraviolet light inactivates existing microorganisms and germs in different types of medium. At the same time further microbial growth is suppressed so that a renewed infestation of the medium with germs does not cause problems; These UV systems are therefore a true in-situ solution for safe and reliable disinfection. Microfloat® sterilizes the entire container interior (liquid, gas space and container surface) and also forms an effective barrier against bacterial contamination via the container ventilation. By applying a suitable UV-C dose, our devices are used for safe and efficient disinfection without chemicals. The inactivation of microorganisms by ultraviolet radiation is based on the interaction of the electromagnetic wavelength in the UVC range with DNA. All microorganisms (bacteria, fungi, algae ...) are vulnerable to wavelengths in the UVC range and development of resistance to UVC radiation is not possible!

In a pure disinfection with UVC, no side effects are to be accepted, as it would be the case with the use of most chemical agents commonly used for disinfection. If necessary, disinfectants such as hydrogen peroxide or ozone can be usefully combined with UV-C radiation. In this combination, a photochemical decomposition of the disinfectant takes place without harmful residues.

The use of floating UV devices is patent-protected!

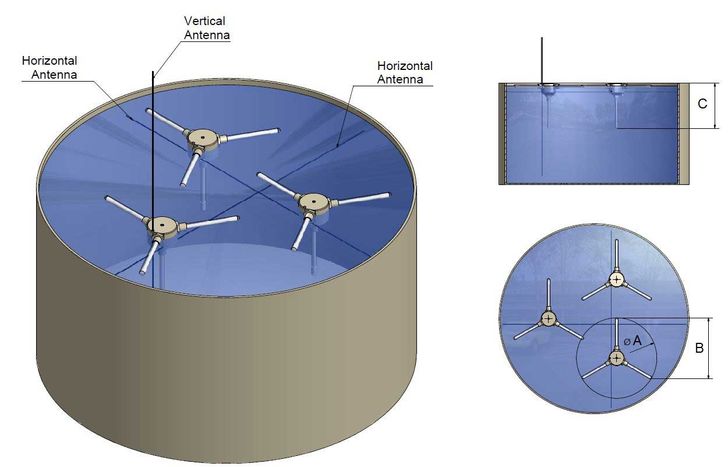

Technical Data - Microfloat®

| Type | Volumen | Electr. Power | UV-Flux at 254 nm | A (mm) | C (mm) |

| Microfloat® 3/0 | up to 4 m³ | 33 W | 12 W | 580 | 120 |

| Microfloat® 3/1 | up to 6 m³ | 44 W | 16 W | 580 | 390 |

Data given above are based on our standard products, tap water quality and fixed tank-size / flow-rate ratio to ensure a sufficient UV-dose and a relable disinfection.

Please contact us to adapt our system for your specific requirements!

All Microfloat® - UV-units are supplied together with an electrical cabinet for all UV-lamps.

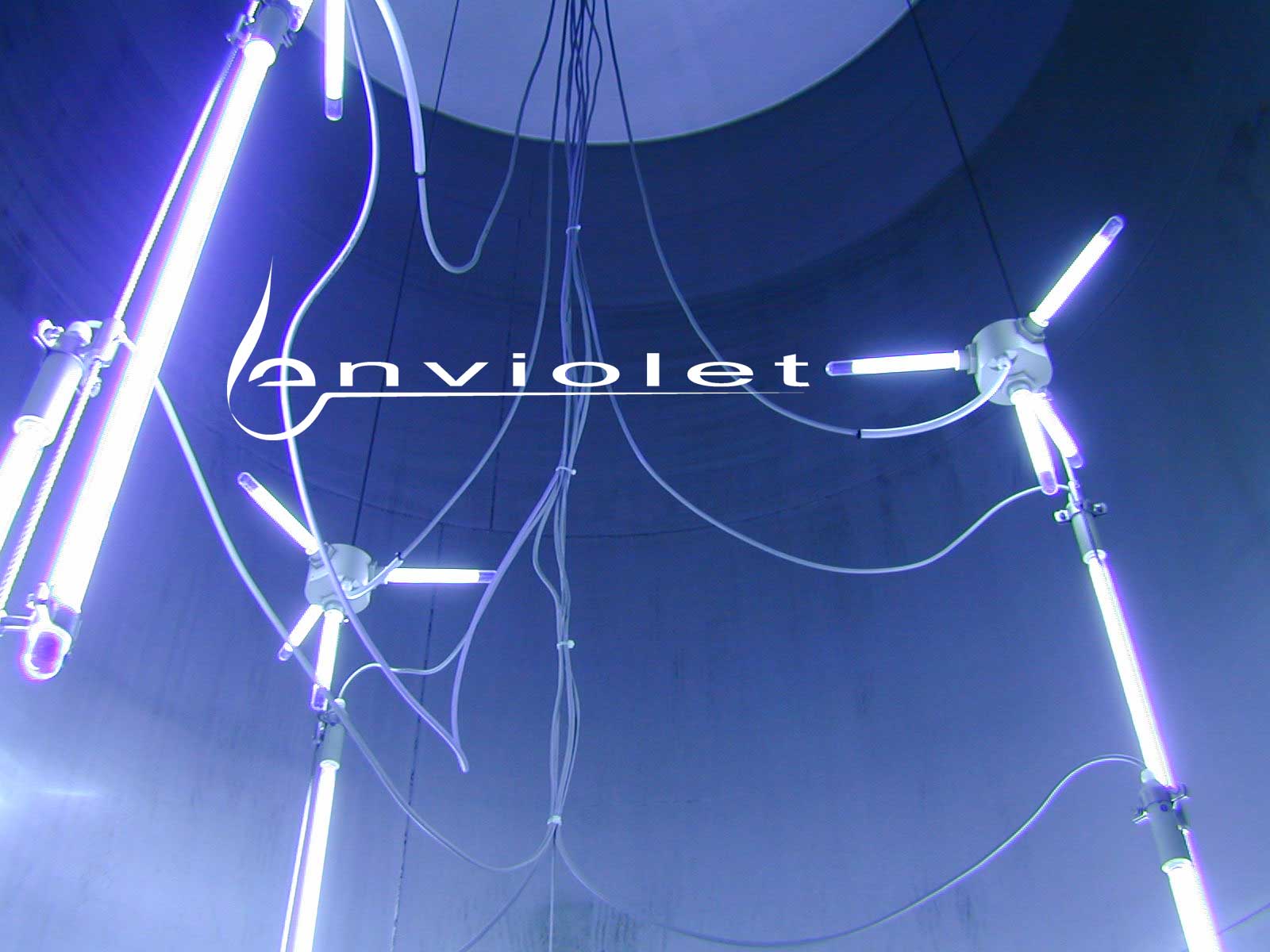

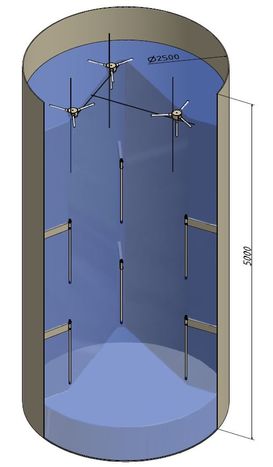

UV-Disinfection with a flexible design

The UV-units Microfloat® and Microspear® can be assembled to complete UV-systems adapted to:

- the shape/ dimensions of the tank

- the flow-rate

- the water quality

In doing so, we can supply optimal customer-fit UV-disinfection, without chemical side effects.

We turn your tank into a UV-reactor!

1. Tank dimensions: LxWxH or DxH in m

2. Filling volume in m³

3. Flow in m³/h

4. Water sample (50mL) or description of the water (e.g.: DI-Water, recycled water, rain water, ...)

5. Construction material (tank)

6. Temperature of the medium

Please send this data to your contact person or to: info(at)enviolet(dot)com .

We will then get in touch to give you a quote of a well-designed system.