uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

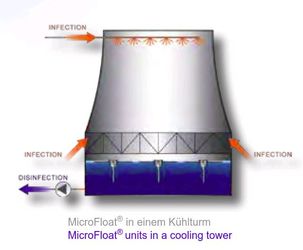

Disinfection of Evaporation Coolers

Reliable supression of legionella in cooling systems

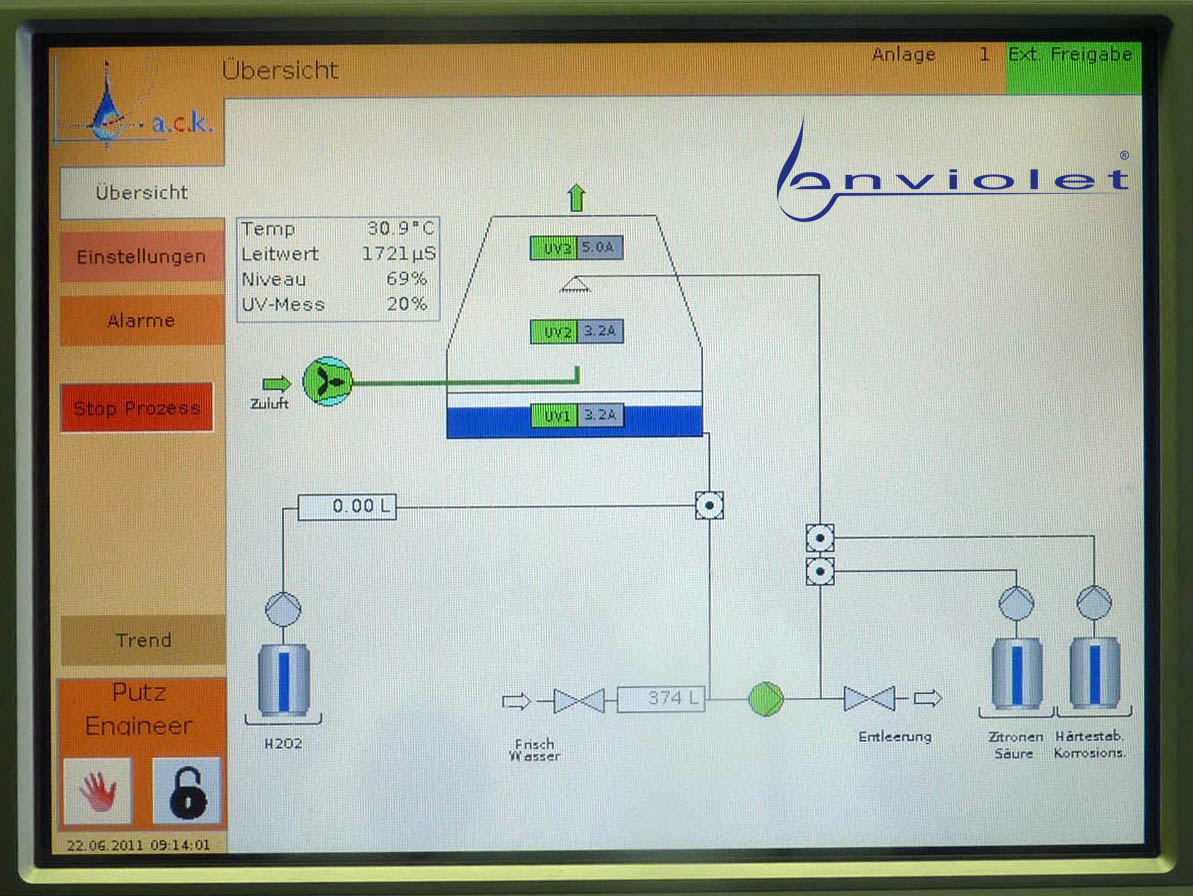

The disinfection and stabilization of cooling towers with UV / H2O2 is reliably and safely possible with the right integration and chemical adjustment to the respective conditions with our solutions "in situ UV disinfection" and "DIP" (Disinfection In Place). The growth of microorganisms (such as legionella) in the cooling circuit is effectively suppressed by ultraviolet radiation to ensure safe and stable operation of the cooling tower.

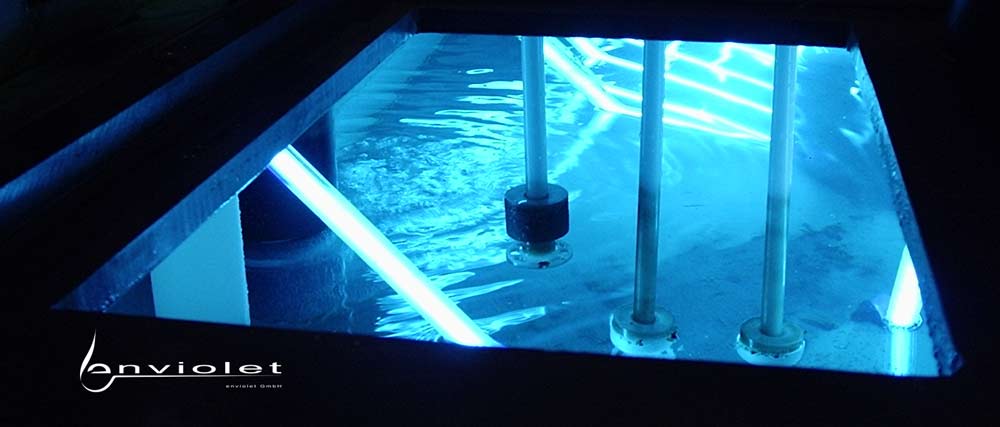

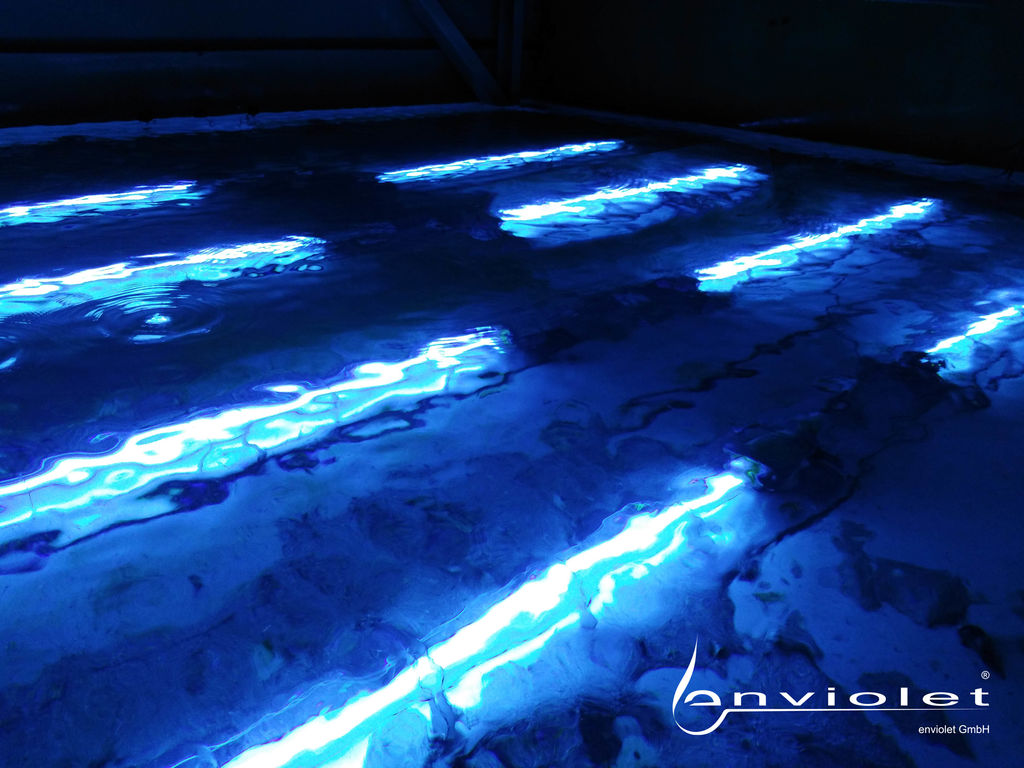

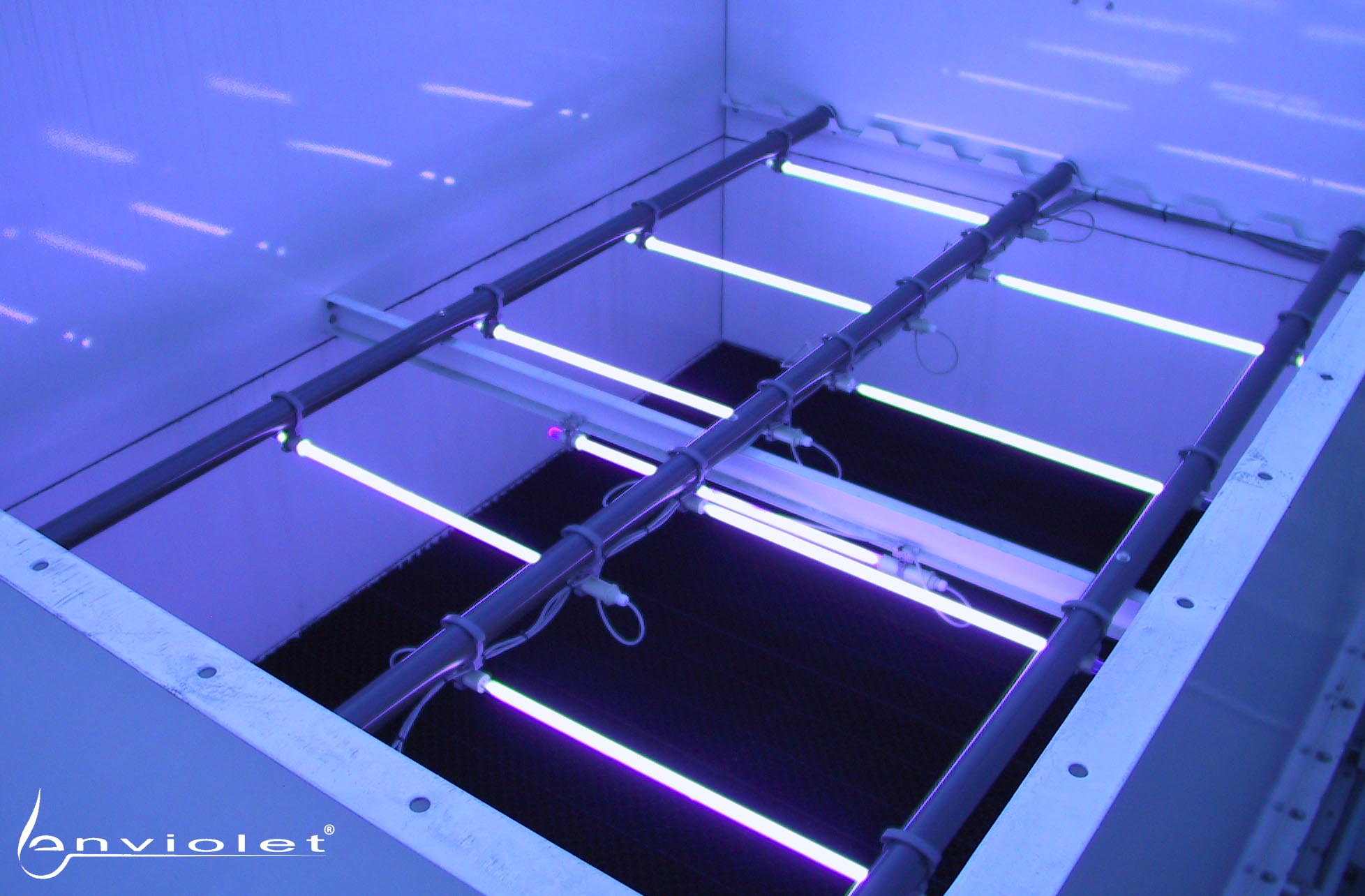

First step is the integration of UV technology in the largest buffer volume (usually the basin of the evaporation cooler) to convert it into a large 'UV reactor'. Most of the circulating water volume is permanently under UV-C radiation. Germs are reliably inactivated and due to the relatively high residence times, an extremely high UV dose can be introduced into the cooling water compared to a UV flow-through-reactor. If necessary equipment that cannot be reached directly by ultraviolet radiation can be disinfected by occasional or regular dosing of small amounts of hydrogen peroxide (H2O2). H2O2 decomposes without residue under UV radiation and causes no corrosion.

Advantages for the user not only result from a very reliable sterilization, but in particular also by cost advantages:

- No development of microbiological resistance against ultraviolet radiation in the UVC wavelength range possible (as is the case with biocides / disinfectants)

- low operating costs (less chemistry, less monitoring effort)

- low maintenance effort

- good water quality (often clear water, no AOX, very low germ counts) and high environmental friendliness during operation

The good water quality without chlorine-based biocides, corrosion inhibitors or hardness stabilizers often makes it possible to infiltrate drainage water. Here we are happy to advise you!

Background, basics and important information for UV-disinfection of industrial cooling towers is summarizes in a publication ready for download here.

Design Data

To generate a solid design and plan the integration of our process into your system, we need the following information:

1. Dimensions of the cooling tower basin (LxWxH; filling level), or the largest buffer volume in the circuit

2. Total water volume in the system (including associated piping)

3. Recirculation rate in m³ / h

4. Cooling capacity in kW or MW

5. Concentration factor

6. Information on the quality of the fresh water (or 100 mL water sample for a free of cost examination in our laboratory)

7. 2-3 current pictures of the plant

Please send this information to: cg(at)enviolet.com.

Please clearly write down the sample code for the water sample sent to you.

On this basis, we can then offer you the right solution for the sterilization of your evaporation cooler.

Publication: UV-Disinfection of cooling towers

Link to the publication.

This publication shows following:

- basic concept behind UV-disinfection of cooling towers

- water chemistry of UV-disinfection of cooling towers

- typical applications for UV-disinfection of evaporation towers

- long time comparison of costs of UV-disinfection of cooling towers with other methods

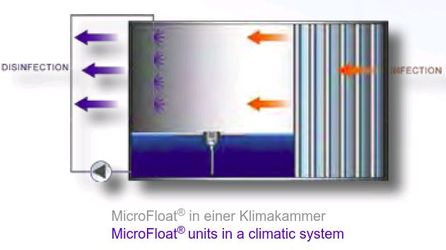

Disinfection of Climatic Chambers and Air Humidifiers

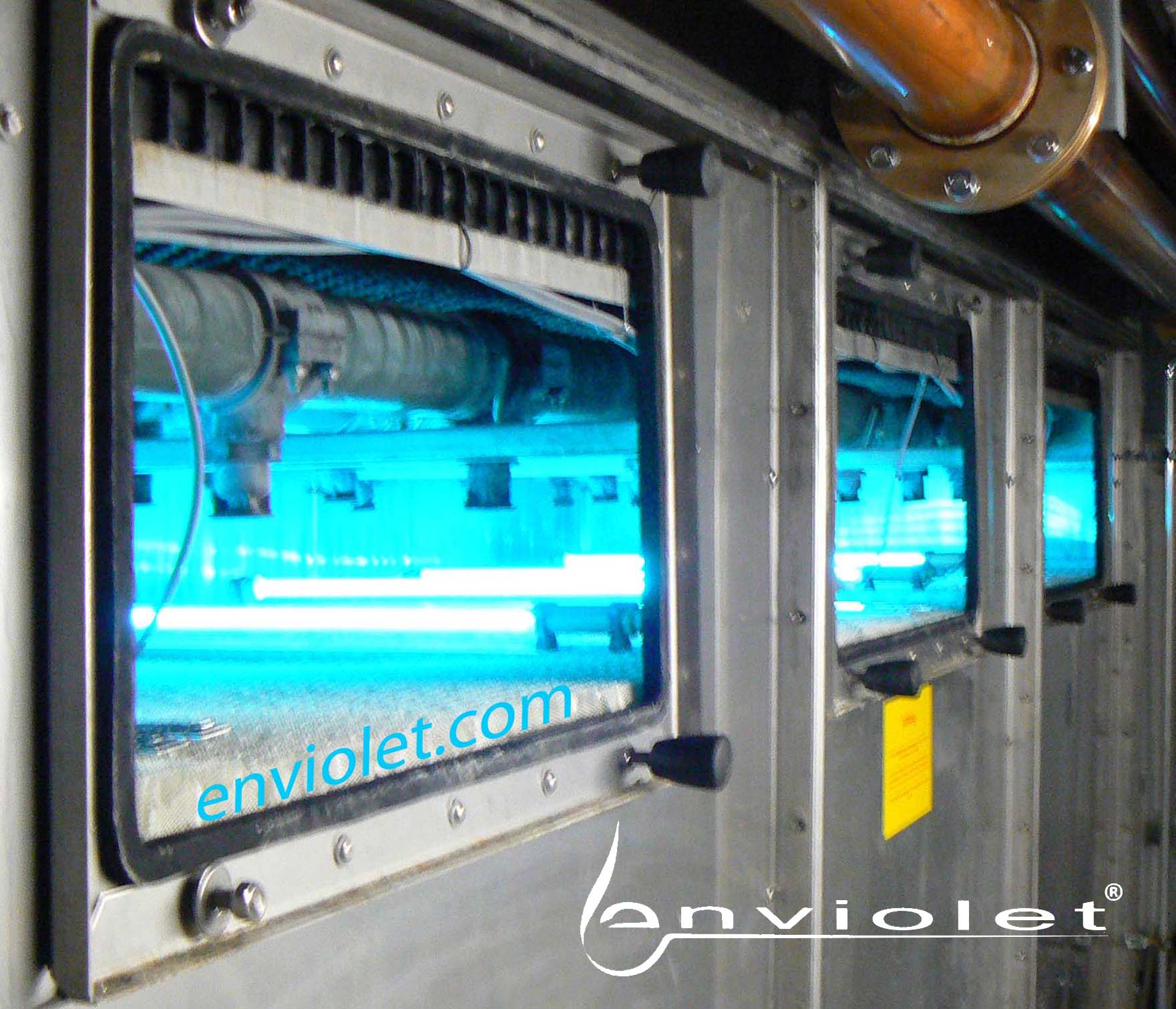

For UV disinfection of water and air in air conditioning applications, e.g .: climate chambers, air humidifiers and fresh air systems, UV disinfection can also be optimally and easily integrated for elimination of contagious viruses like SARS-CoV-2.

Microfloat® and Microspear® are established and tested systems for safe disinfection and reliable removal of any kind of microorganism (like legionella, or corona virus).

For optimal performance and safe operation we constantly evolve our systems to improve and ideally adapt it to new developements like the COVID-19 pandemic.

Are you interested in the UV disinfection of climatic chambers, air humidifiers and fresh air systems (e.g. for prevention of COVID-19)? Then you should contact cg(at)enviolet.com!