uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

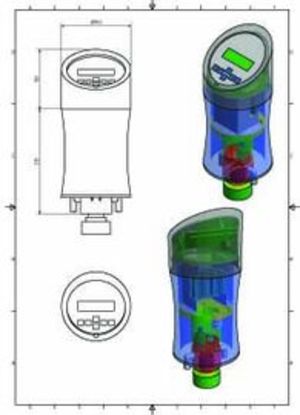

LevelAir - Level sensor

The level sensor for constructors

Who hasn't experienced trouble with analog and digital level sensors? After installing a fully automatic installation, it fails because a level sensor gives a wrong signal or no input. It does not matter if it is an ultra sonic sensor, which is disturbed by vapor, foam or the bevelled bottom of the tank or if it is a mechanical floater, which jams due to fouling or mechanical blockage. All of these will aways result in expenses, which will end up having to be covered by the supplier of the installation or the operating company.

a.c.k. aqua concept and enviolet look back on ten years of experience of engineering special plants and knows the importance of level sensor technology. Especially among waste water plants the problem whittles down to these details. We have combined our experience into one level sensor to give it all the properties a plant engineer needs.

Your advantages with LevelAir:

- LevelAir is very cost effective.

- LevelAir shows no corrosion.

- It contains no moving parts.

- Display of the filling level in meters and in %, as well as display of the volume in m³. The display is illuminated.

- The density of the liquid is adjustable.

- LevelAir does not have to be calibrated.

- There are four dry contacts available, which switch at different and adjustable levels. They can be used as normally open contact or as break contact element to switch up to 1 Ampere.

- A DC 4 - 20 mA output port is available to be used for an analogous input by an external controller.

- The damping of the signal is adjustable.

- The level signal will not be impacted from a varying pressure in the tank atmosphere.

Extremely low consumption of air and electricity.

Principle of operation

A pressure sensor measures the static pressure in a dip tube without making contact with the fluid.

Levelsensor is fixed with a threaded socket (DN25) on top of a dip tube which leads to the

bottom of the tank.

Air flowing in prevents that the liquid reaches the tube. Thus, it is ensured that no corrosives gases or vapour damage the pressure sensor.

A pressure compensation pipe corrects the level measuring. Therefore, varying pressure in the tank atmosphere will not affect the measurement.

Plug and play. Use only the standard threaded socket (part of the delivery volume) to thread it on top of a dip tube, connect the cables to the generously ample designed clamps and finely connect it to the pressured air, which will normally always be available.

That’s all!