uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

Ecofriendly Production at enviolet

At enviolet, the new resource and energy age began a long time ago:

Since 2011, an active contribution to regenerative and environmentally friendly energy production has been made with the installation of a modern photovoltaic system and a CHP for the generation of electricity and heat.

Since 1998, enviolet and a.c.k. aqua concept have been pursuing the goal of "environmentally friendly production" in the manufacture of high-quality reactors for UV oxidation, AOP and recycling processes. At that time we were ridiculed for such measures, but today we are exactly where everyone wants to be.

There are also programmes to encourage employees to use a company bicycle and the "non-smoker" motivation programme.

Recycling

This began back in 1998 with the introduction of a recycling system for burnt-out UV modules that is unique in the UV world.

We also separate materials by type (iron, stainless steel, copper, glass, quartz glass, PP, PE, PVDF) and recycle them internally or externally. Packaging materials are almost completely reused.

Sustainable energy generation (see table "Overview of energy generation").

In 2012, a modern photovoltaic solar system (PV) with an output of 60 kW was put into operation.

The combined heat and power unit (CHP) is operated on demand and supplies the business with heat and electricity during the season when the solar system generates little energy.

The surplus of sustainable energy is fed into the electricity grid, with a surplus of 50-80% sustainable energy being fed into the public electricity grid.

Minimising energy consumption

At the turn of the year 2022/2023, the entire lighting system at enviolet and a.c.k. aqua concept was replaced. By using highly efficient new lightning technology, the energy consumption for lighting the production area was reduced by 66%, with better illumination for our workers. With the help of motion sensors in the technical warehouse, electrical warehouse and consignment warehouse, energy consumption is optimised even further.

In the office area and in the laboratory, the lighting has also been optimised with a saving of 52% energy for the same illumination of the workplaces, some speces even offer dimming options.

Environmental protection in practice

In this way, our modern UV systems for environmental technology make a major contribution to active environmental protection right from the production stage, and every customer who chooses a system from enviolet lives this attitude with us.

Overview energy production vs. consumption

enviolet produces more sustainable energy than enviolet needs to operate the company!

| Year | Energy consumption through production, lighting, IT | Energy generation through PV | Energy generation through BHKW | Generation/consumption |

| 2019 | 50559 kWh | 57228 kWh | 31582 kWh | 176% |

| 2020 | 59641 kWh | 55712 kWh | 30187 kWh | 144% |

| 2021 | 69834 kWh | 49227 kWh | 61875 kWh | 159% |

| 2022 | 54166 kWh | 53593 kWh | 28500 kWh | 152% |

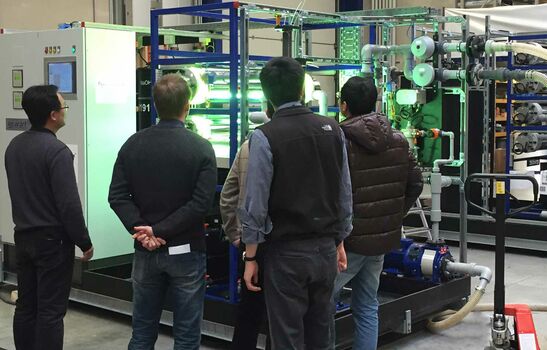

Enviolet as producer of AOP-plants

Enviolet produces units and plants primarily in its own facilities.

Smaller units are wholly manufactured in our factory, while for bigger plants, the central components are manufactured at our site and completed at our customer's site.