uv reactors, photo-oxidation, advanced oxidation (aop), recycling & engineering

for industrial use

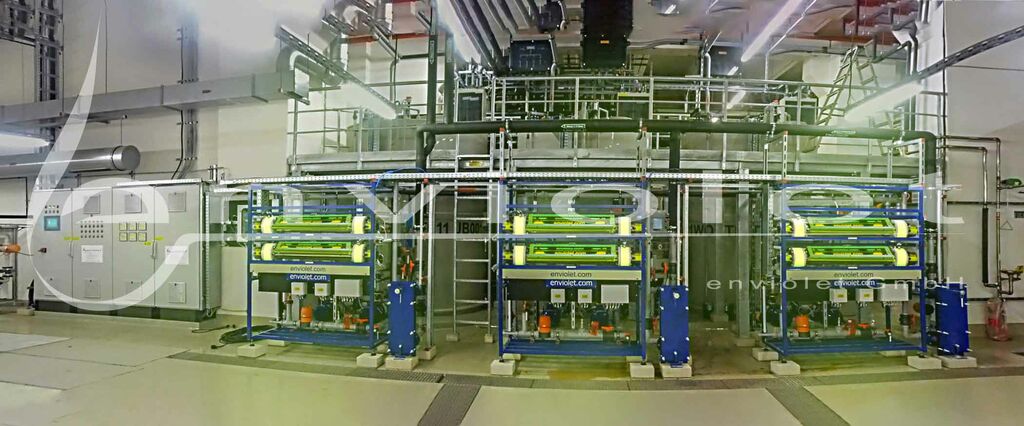

Wastewater treatment in the semiconductor industry

Advanced oxidation for the treatment of semiconductor wastewater

In the semiconductor industry, wafer fabs generate a wide variety of different production wastewaters and spent production solutions due to complex manufacturing processes such as chemical mechanical polishing (CMP), or various rinsing or etching processes performed on wafers. These wastewaters and solutions contain a number of potentially problematic ingredients such as:

- complexing agents/ chelates - such as cyanide or PBTC

- Organo-nitrogen compounds - such as pyrazole, triazoles, or tetramethylammonium hydroxide (TMAH)

- Toxic compounds

- Organic compounds with poor biodegradability

- Excess H2O2 or ozone from rinsing processes

- Spent production solutions such as sulfuric acid (H2SO4) contaminated with H2O2 from etching processes with piranha acid / peroxomonosulfuric acid.

These substances enter the wastewater system of the fab after the manufacturing process individually, or in the worst case as a mixture. This complex mixture and the individually already problematic ingredients in semiconductor manufacturing pose difficult tasks for conventional methods of wastewater treatment, especially when an economical, environmentally friendly and compact treatment is required.

Modern and sustainable treatment of wastewater in semiconductor production

Advanced Oxidation for wastewater in wafer fabs

With oxidation processes (Advanced Oxidation Process, Advanced UV-Oxidation Process, UV-Oxidation) from Enviolet, for example for the semiconductor industry, technically sophisticated and individually adaptable solutions for the handling of the above mentioned compounds can be realized in wafer fabs through advanced oxidation processes.

- Complexing agents (such as cyanide or PBTC)

can be degraded by UV-oxidation -> treatment of chelate wastewater

- Toxic or interfering individual compounds

can be reliably removed by UV-oxidation -> degradation of single substances

- Organo-nitrogen compounds (such as pyrazole, triazoles or TMAH)

can be effectively degraded by AOP processes

- Organic compounds with poor biodegradability can be

become biodegradable by advanced oxidation -> increase of biodegradability

- Excess H2O2 from rinsing processes

can be converted without problems. We often combine this with joint treatment of other problem wastewaters.

- Spent production solutions such as sulfuric acid (H2SO4) contaminated with H2O2 from etching processes with piranha acid / peroxomonosulfuric acid

can be recycled and purified for other applications by removing the H2O2 and other contaminants.

Enviolet's UV-based AOP (Advanced Oxidation Process Equipment) systems are able to treat even optically dense media in wafer fabs economically and are ideally suited for all applications in the semiconductor and photovoltaic industry. A major advantage of the UV-AOP processes is that no secondary waste of problematic nature is produced, as is the case with other processes (precipitation, evaporation, etc.). In the semiconductor industry we often combine our oxidation processes with biological oxidation (municipal or industrial).

Treatment of semiconductor waste water by advanced oxidation

AOP for wafer fabs in different applications for wastewater treatment (e.g. for slurry wastewater)

Advanced oxidation processes of enviolet can be customized by feasibility studies to ensure an optimal result of the oxidation of the semiconductor waste water in compliance with all limits.

For the pilot phase a.c.k. aqua concept GmbH offers a wide range of pilot plants for rent.